How would you like me to build your next home? If you have read my biography and several of my past columns, my guess is you trust the way I would do things. The trouble is, I can't be there to build your home in person, but I can tell you or your builder how I would do hundreds of things if I was there with my tool belt on.

Now featuring a link inside the PDF file to allow you to download a copy of the specifications in Word DOC format. You can now copy and paste and update your own house plans.

The New House Specifications contains over three-hundred descriptive specifications - excerpts below - that enhance the structure and value of your new home. I have multiple specifications in each of these Exterior categories:

Asphalt, Blacktop and Tar and Chip Driveways

Asphalt, Blacktop and Tar and Chip Driveways - Backfilling

- Brick, Block or Stone Exteriors

- Building Site - Lot

- Concrete Driveways

- Decks

- Doors

- Downspout Drainage Piping

- Fencing

- Footings, Foundations and Piers

- Gutters and Downspouts

- Housewrap

- Painting and Staining

- Plumb and Square

- Retaining Walls

- Roof Ventilation

- Roofing Materials

- Rough Grading

- Sewer or Septic Drain Line

- Sidewalks and Patios

- Skylights

- Structural Bracing

- Stucco

- Trim Lumber

- Vinyl Siding

- Water Service Line

- Windows

These Interior topics are then discussed:

- Attic Access Stairway

- Bathroom Plumbing Fixtures

- Below Slab Rough Plumbing

- Central Vacuum

- Ceramic Tile

- Closets

- Concrete Slabs -Basement, Garage, etc.

- Dryer Vents

- Drywall / Plaster

- Electric Branch Circuit System

- Electric Service Panel

- Finished Flooring

- Fire Sprinklers

- Framing Connectors

- Garage and Garage Doors

- Heating and Cooling Systems

- Insulation

- Low Voltage Wiring for Door Chimes, Telephone Computers, etc.

- Natural Gas or LP Gas Lines

- Painting and Staining

- Plumbing System

- Roof Trusses

- Rough Lumber

- Staircases

- Storm Shelter

- Structural Steel

- Termites

- Vapor Retarders

- Ventilation Fans

- Wall Blocking

- Wall Framing

- Wallpaper

- Water Heaters

- Wood Subflooring Systems

- Woodwork and Baseboards

Do you need more convincing? Here are some specifications from the just the Exterior Concrete Slab section:

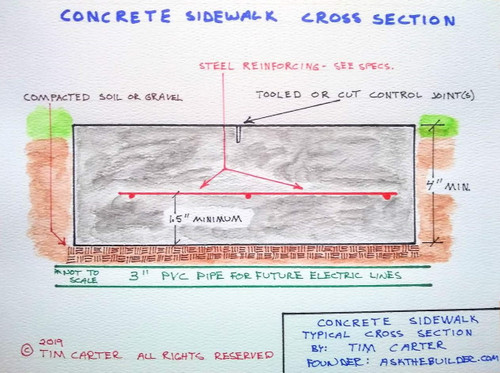

".....All poured concrete sidewalks and patios shall contain concrete that has a design strength of no less than 4,500 psi. No water can be used on site to make the concrete more plastic nor can water be used as a finishing aid.

All slabs shall be a minimum thickness of 4 inches. A 5-inch thick slab is preferred.

All exterior concrete shall contain 1/2-inch diameter steel reinforcing rods and these shall be placed at 2 foot centers in both directions. This steel should be in the lower third of the slab with a minimum of 1 and 1/2 inches of concrete between the steel and the compacted sub-grade. 42# mesh will also suffice for steel reinforcing.

All exterior concrete shall contain 1/2-inch diameter steel reinforcing rods and these shall be placed at 2 foot centers in both directions. This steel should be in the lower third of the slab with a minimum of 1 and 1/2 inches of concrete between the steel and the compacted sub-grade. 42# mesh will also suffice for steel reinforcing.

Immediately after the final finish is complete, apply a clear-drying liquid curing compound to the fresh concrete.

Control joints shall be cut in all slabs to prevent random shrinkage cracks. These joints shall be a minimum depth of 1/4 the thickness of the slab. They can be saw-cut as soon as the concrete can withstand foot pressure and the action of the saw without harming the finished surface. Under no circumstances shall the joints be cut later than 24 hours after the concrete is hard enough to walk on without harming the finish. ..."

Or how about these specifications from the Interior Plumbing section:

".....Rough in basement bathrooms and utility sinks whenever possible to save money. Cutting into concrete slabs to create basement bathrooms at a later date is a very expensive proposition.

Water supply lines shall be sized to minimize water pressure and volume losses. Use 3/4 inch minimum pipe size to feed all fixture groups. Branch off this 3/4 inch pipe to each fixture with its own 1/2 inch pipe. Never serve two fixtures with a 1/2 inch pipe.

Water supply lines shall be sized to minimize water pressure and volume losses. Use 3/4 inch minimum pipe size to feed all fixture groups. Branch off this 3/4 inch pipe to each fixture with its own 1/2 inch pipe. Never serve two fixtures with a 1/2 inch pipe.

All shut off valves under all fixtures shall be ball valves.

To minimize noise in water supply pipes, consider using type L copper if copper is being used as your water supply pipe. Type L is thicker and absorbs turbulence much better than thinner type M copper. Larger diameter pipe sizes help to minimize water noise as the water flows slower through these pipes to satisfy a given fixture demand.

The primary water supply line serving the entire house shall be 1-inch diameter until it passes and serves the water heater and feeds the first major fixture grouping.

Large hot tubs or large capacity whirlpool tubs must be served with minimum 3/4 inch supply piping. These fixtures almost always require separate water heaters to produce the vast amounts of hot water required to fill these vessels.

Water hammer is eliminated by using the larger supply piping as mentioned earlier.

If copper tubing is used for water supply, all joints must be wiped clean of excess soldering flux. Wipe pipes with a rag soaked in mineral spirits until each joint is perfectly clean. Acid flux that is not cleaned from copper pipe can cause future corrosion that causes leaks.

Investigate if your area suffers from aggressive water. If so, be sure you use the correct water supply piping that will not suffer corrosion from the aggressive water.

If you plan to have a water softener installed, pipe outdoor hose bibs so they do not pull water from the water softener. However, one soft water hose bib should be installed in or near the garage. If you wash your car and rinse with soft water, water spotting does not happen...."

The Checklist is available to you as an immediate download once your order is processed. After completion, you will be taken to a page with a download link for the Checklist file. In addition, you will receive a confirming email. In the Cart Items section of the email, there will be a download link. Just click on the link and the Checklist will be downloaded to your computer. The downloaded file can be read using the free Adobe Reader software.

You have nothing to lose and everything to gain. If you don't feel this product is worthwhile, just email me and I will issue a credit.